News

How the circular economy could change the bicycle industry

Reuse instead of throw away - the principle of the circular economy is currently on everyone's lips. More and more bicycle companies are also looking at moving away from the classic, linear economic model towards more sustainable business strategies. It is a change that brings numerous opportunities but at least as many challenges. An overview.

Cycling is good for the climate and the environment - it's a phrase you hear a lot these days. However, this is only half the truth: while exercising in the fresh air keeps the eco-balance in the green for oneself - for example, because one leaves the car in the garage in favour of the bicycle - bicycles nevertheless carry a heavy CO2 burden with them. It is estimated that the global sports industry is responsible for CO2 emissions of 300 to 350 million tonnes per year. Although the bicycle industry accounts for only a small part of the economic volume of the global sports world, this figure clearly shows that, compared to other means of transport, bicycles help to save CO2 on the one hand. On the other hand, it also contributes to pollution.

"You can reckon with several hundred kilograms of CO2 per bicycle produced. On top of that, there is the consumption of resources and later the scrap produced by a discarded bicycle," explains Erik Bronsvoort. The Dutch sustainability expert has been committed to making our planet a better place for years. In 2020, he published the book "From Marginal Gains to a Circular Revolution" together with his colleague Matthijs Gerrits. Its tenor: when it comes to the topic of sustainability, the bicycle industry also has a duty - despite the largely environmentally friendly reputation of two-wheelers. His appeal: "Ultimately, therefore, it comes down to using a bicycle for as long as possible - in order to reduce the CO2 footprint per kilometre."

Long supply chains and little recycling

What Bronsvoort means becomes apparent when you look at the lifecycle of a bike. A bicycle consists of more than 2,000 parts. These are produced in various locations around the world, especially in Asia. The majority of these are metals and composites that are only shipped to Europe or North America for final assembly. "It's a huge supply chain. The material extraction, the production, the transport, the final production, the way to the bike shop - all this leaves an ecological footprint," Bronsvoort reports. How this journey translates into numbers is examined by the US bike manufacturer Trek in a sustainability report published in 2021: The mountain bike "Marlin" comes to around 116 kilograms of CO2. The "Rail" e-mountainbike even produces 220 kilograms of CO2. However, the footprint of a bicycle is still significantly lower than that of a car. A newly produced car produces five to 30 tonnes of CO2, depending on the model.

The Trek sustainability report also suggests that the supply chain is only one side of the coin. Thus, the study does not include potential costs for recycling or disposing of frames and components after use. In fact, few parts of a broken bicycle are reused. Instead, most bikes end up in the scrap yard. "The reason for this is that most companies in the bicycle industry work with a linear economic model - also called a throwaway economy. Raw materials used for a product are not returned to the cycle after their useful life in this type of economy, so that they could be reused," says Bronsvoort and emphasises: "The solution to this problem would be to move to the so-called circular economy."

The circular economy as a possible solution

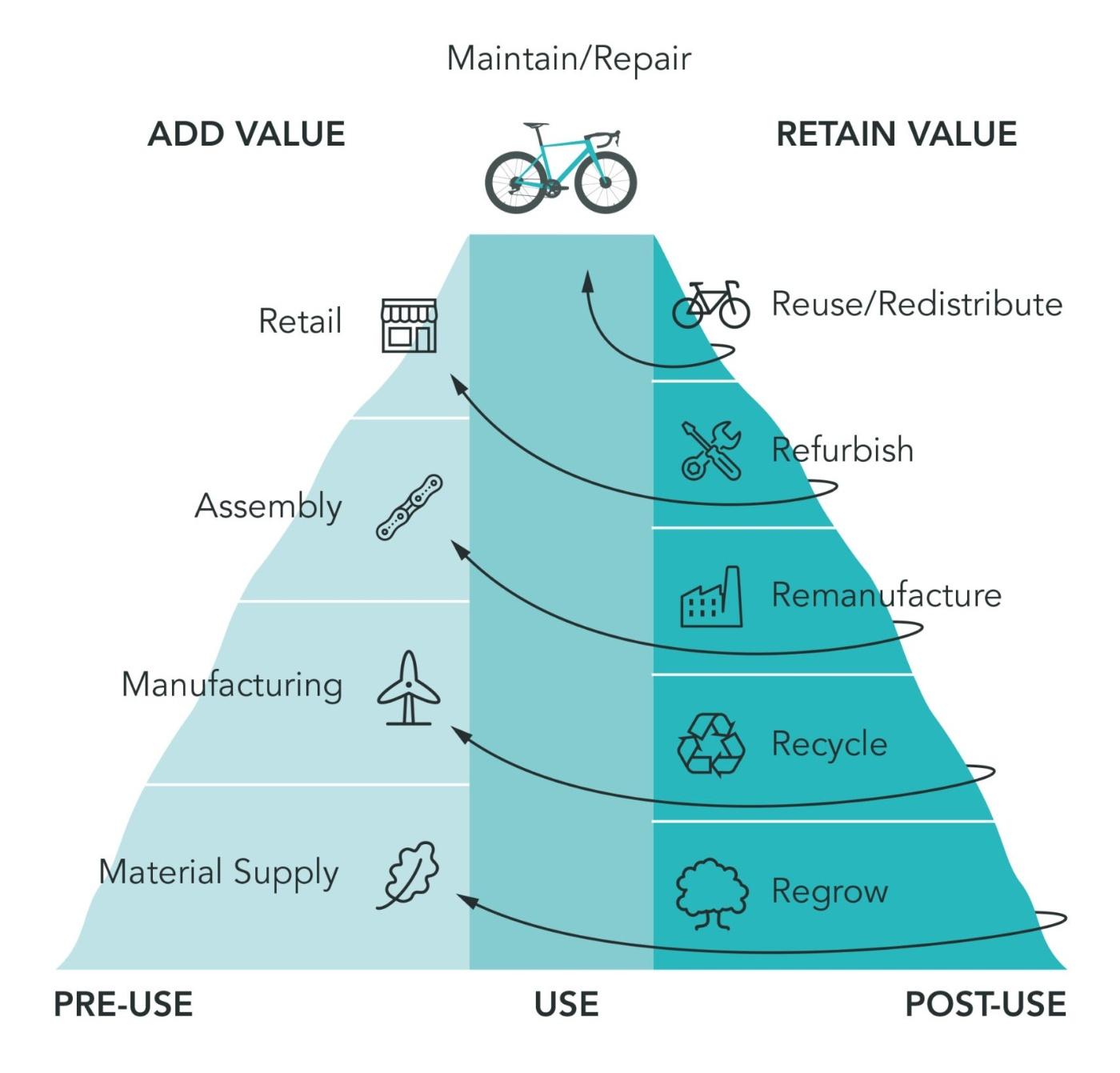

In principle, the circular economy is an economic approach that promotes the reuse of materials and the regeneration of products and resources. In the circular economy, waste is seen as a resource that can be used to produce new products and services. The aim is to close the loop of resource use so that materials and products are used again and again instead of being wasted. The circular economy thus aims to reduce waste, conserve resources and prevent pollution. "To achieve these goals, it is important to develop a closed-loop system in which all materials and products are reused or recycled," Bronsvoort explains.

Circular economy vs. linear economy at a glance

| Linear economy: | Circular economy: |

|---|---|

|

|

- Circular economy is an economic model discussed in the course of many companies' sustainability offensives. |

Transferred to the bicycle industry, this would mean that all materials and parts needed to build a bicycle are in a cycle. During production, it would already be ensured, that the components are made from renewable or recycled materials. In addition, the products should be used for a longer amount of time. "And if something does break, it should be quick and easy to repair or replace it. At the end of their life, the bikes then return to the respective company so that it builds new bikes from them - or the parts are returned to the cycle of nature in an environmentally friendly way," says Bronsvoort, who adds: "In the end, it would be a win-win-win situation: for the end users, for the industry and for our planet."

Big challenges for all involved

A bicycle built with the idea of a circular economy in mind - at the moment, however, the bicycle industry is still far from this scenario. One reason is the current structures. If you look at today's bikes and components, you quickly realise that there are many different standards and few interchangeable parts. This often makes it more convenient to replace the whole part straight away than an individual component. "Instead of replacing a worn sprocket, you get a new cassette," says the Dutch expert, giving an example. He himself had started an attempt to open a bicycle shop that builds new bicycles from old parts a few years ago - but without success. "It simply takes too long to find the right components, assemble and build the bikes."

Book tip: From marginal gains to a circular revolution

What might a sustainable bicycle industry look like? In their book, authors Erik Bronsvoort and Matthijs Gerrits describe on 160 pages how the change to more climate- and environmentally friendly bicycle products could take place. The tenor: small steps are not enough, a revolution is needed. The book is currently only available in English, but a German version is being planned, according to Erik Bronsvoort. More information is available at www.circularcycling.nl

The requirements for a bicycle that would be built according to the standards of the circular economy also show how great the challenges are for all those involved: such a bicycle should not only have parts that are as easily replaceable and reusable as possible, but should also be as resilient and durable as possible. It should also be easy to repair. Last but not least, raw materials should be used that are easier to recycle. Aluminium, for example, is considered more sustainable than carbon fibre - because it can be easily recycled at the end of its life.

A consensus is needed in the industry

Another solution could be a so-called digital material passport for a bicycle - in other words, a database listing which products and materials have been processed in a bicycle and where they come from. "That would certainly make the industry rethink. It would also be good in that such a material passport would greatly simplify the work of recycling companies. The work of dealers would also be simplified because further information such as warranty periods of individual parts etc. could be noted," says the Dutchman. Despite all the ideas - in conclusion, however, he also points out that there is still a long way to go here. Bronsvoort: "We are at the beginning of a revolution."

Circular economy - these bicycle companies show the way

Building a new bicycle from old bicycle parts? In fact, there are already bicycle companies using similar economic models to make their bikes. These companies use product waste or recycled materials instead of simply disposing of the waste. Below we present three companies from the bicycle industry that are already working on or experimenting with the circular economy.

| Swapfiets (Netherlands) |

|

No purchase costs, no down payment and a subscription that can be cancelled monthly - the Dutch company Swapfiets has conquered European cities in no time with its subscription model. Among other things, the subscription model means that broken bicycles are repaired or replaced within 48 hours. All parts are therefore particularly robust or designed in such a way that they can be easily replaced or reconditioned. www.swapfiets.com |

| Roetz Bikes (Netherlands) |

|

"Every year, about one million bicycles are thrown away - even though essential parts such as the frame are in good order," says the Roetz website. This was the impetus for founding the company Roetz Bikes in 2011. In the Roetz Fair Factory in Amsterdam, new bicycles are made from discarded bicycles, mainly city bikes and e-bikes for the city. In the meantime, a circularity of around 30 percent has been achieved. In the future, they want to increase this value significantly. www.roetz-bikes.com and www.roetz.life |

| Vaude (Germany) |

| Not a bicycle manufacturer, but a well-known producer of bicycle clothing. For years, Vaude has been considered a pioneer when it comes to sustainability. One of the company's goals is, among other things, the circular economy. In the current Vaude sustainability report, it says: "Most of Vaude's waste is recycled, but residual waste remains our problem child - even though we upcycle quite a few material scraps." In 2022, the company will be climate neutral for the first time. This is achieved, among other things, through a mixture of sustainability initiatives and compensation payments. www.vaude.com |