Things will run smoothly in the future: The automotive industry on the threshold of the circular economy

It is the buzzword of the hour - and thus a hot topic for the IAA Mobility Visionary Club: circular economy promises mobility that conserves resources. For the automotive industry, it is both an opportunity and a challenge. About a paradigm shift and its potential.

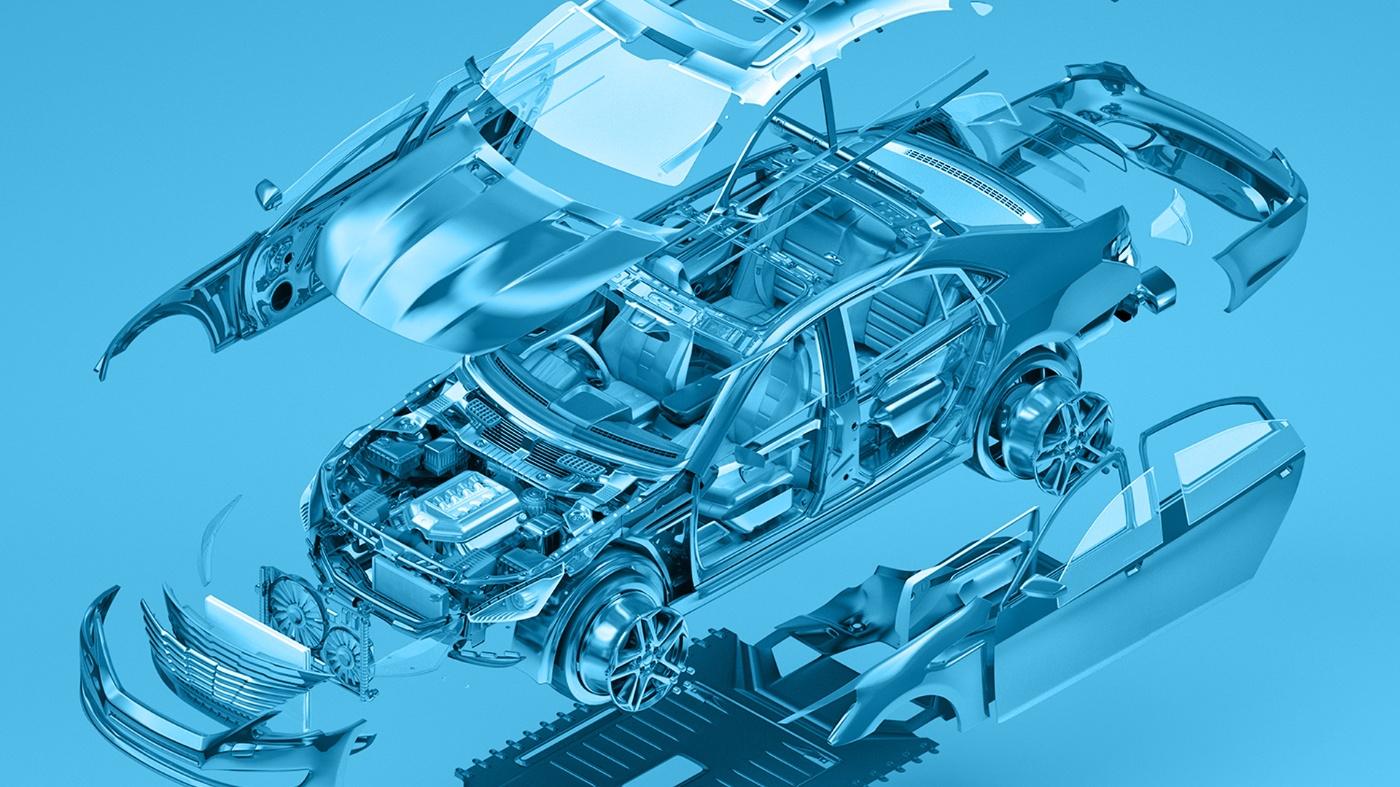

The vision is beautiful: a world in which we produce new things without consuming new resources. This is exactly what circular economy means in the final analysis: as little as possible is wasted, everything is designed, built and remanufactured so that it can be used again for as long as possible. This creates a closed loop - as a counter-design to the throwaway mentality of the linear economy. This makes it possible to use finite resources sparingly and reduce CO2 emissions. According to a study by the Ellen MacArthur Foundation, 45 percent of global emissions are caused by the manufacture of products.

So there are good reasons for the automotive industry and the IAA Mobility Visionary Club to address this issue. After all, in order to achieve the Paris climate targets, the industry has also written reducing emissions in production and the supply chain into its specifications.

Much more than recycling

So simply recycle more and everything will run smoothly? It's not quite that simple. Circular economy means a paradigm shift - along the entire value chain. Daniela Bohlinger, Head of Sustainability Design BMW Group, explained in the IAA Mobility Visionary Club discussion: "We have to arrive at completely new principles for how we build our cars. Circular economy means starting from scratch again."

If recyclability becomes a premise, it must be thought into every product from the outset: for example, through the use of recyclable materials, components that are easier to disassemble, and transparency throughout the supply chain. Materials must also be able to withstand the industry's high demands on quality and cost-effectiveness: Not all raw materials can be reprocessed without loss of quality. "The key here is to plan from the outset how we can reuse as many components as possible at the end of the product life cycle - in automotive construction or, precisely, for another purpose in another industry," explains Fabrizio Barillari, Head of Product Portfolio Management Sustainable Solutions at Röchling Automotive, at the Visionary Club. One challenge. There are others: How can the use of often even more expensive recycled materials be promoted? In what quality will they be available? And in what quantity? Many questions are still open.

Growth factor and job engine

Alexander Meyer zum Felde, Partner and Associate Director at the Boston Consulting Group, is nevertheless optimistic about the switch in the discussion: "The development is progressing quickly, and it is driven by business cases." That's because the model promises growth. "It's about preserving value that you already have. That's the beauty of it," adds Luise Müller-Hofstede, director of business development at Circulor, a provider of supply chain traceability solutions.

According to estimates, the transition to a circular economy could unlock $4.5 trillion in global GDP growth by 2030 and create 700,000 new jobs in Europe. It could also make us less dependent on imported raw materials. Policymakers are also driving the issue; circular economy is an important part of the EU's Green Deal.

New forms of cooperation and new business models

The transformation is already underway, with industry building battery recycling plants, working on reusable materials and playing out the model on studies such as BMW's i Vision Circular. The vehicle was designed around the principles of the circular economy. In the long term, however, the industry will need new business and collaboration models and the use of cutting-edge technologies. Tracking across the supply chain, organized in the blockchain, could enable the traceability of materials in a digital ecosystem where suppliers, manufacturers and recyclers work together. For circular business models, automotive manufacturers would also have to tackle the use of vehicles in a consistent way - and thus take a further step toward becoming a mobility service provider that offers car sharing as well as, for example, take-back systems for vehicles.

Such an approach would be in line with the trend: "We will increasingly see customers demanding such concepts," says Carla Woydt, Director Sustainability at aware, a platform for sustainability. So what does it take to shape the linear economy into a circle? Investments, technologies, collaborations and a consistent will to implement the model, the panel at the IAA Mobility Visionary Club agrees. "We have no choice at all," says Luise Müller-Hofstede. "Everything simple has already been done."

1 Ellen MacArthur Foundation, Completing the Picture: How the Circular Economy Tackles Climate Change (2019) www.ellenmacarthurfoundation.org/publications

2 Peter Lacy and Jakob Rutqvist, Waste to Wealth: The Circular Economy Advantage, New York and London: Palgrave Macmillan, 2015.

3 Pressemitteilung der Europäischen Kommission, 11.3.2020: Neuer Aktionsplan für die Kreislaufwirtschaft, https://ec.europa.eu/commission/presscorner/detail/de/ip_20_420