News

E-fuels: Clean mobility using the combustion engine

The complete switch to e-mobility could still take decades. Is this the time for synthetic fuels? Photo: © Porsche AG

E-fuels are seen as a key component in the transport revolution, alongside battery-based electric mobility. Above all, they have the potential to make heavy distribution transport, shipping and aviation CO2-neutral. And they also enable combustion engines, which will still be on our roads for many years to come, to run and to be environmentally friendly, without converting the drive engineering or the petrol station network.

Anyone who drives a car is wishing for precisely this: driving that respects the environment, without involving compromises and without having a bad conscience about it. For that reason, some people are switching over to an e-car. But for many people still driving cars with a combustion engine, this option will only present itself in some years’ time. The experts are assuming that it may take up to 40 years before transport has switched over to e-mobility. One possibility for getting around in an environmentally-friendly way and CO2-neutral, regardless of the drive engineering, is e-fuels.

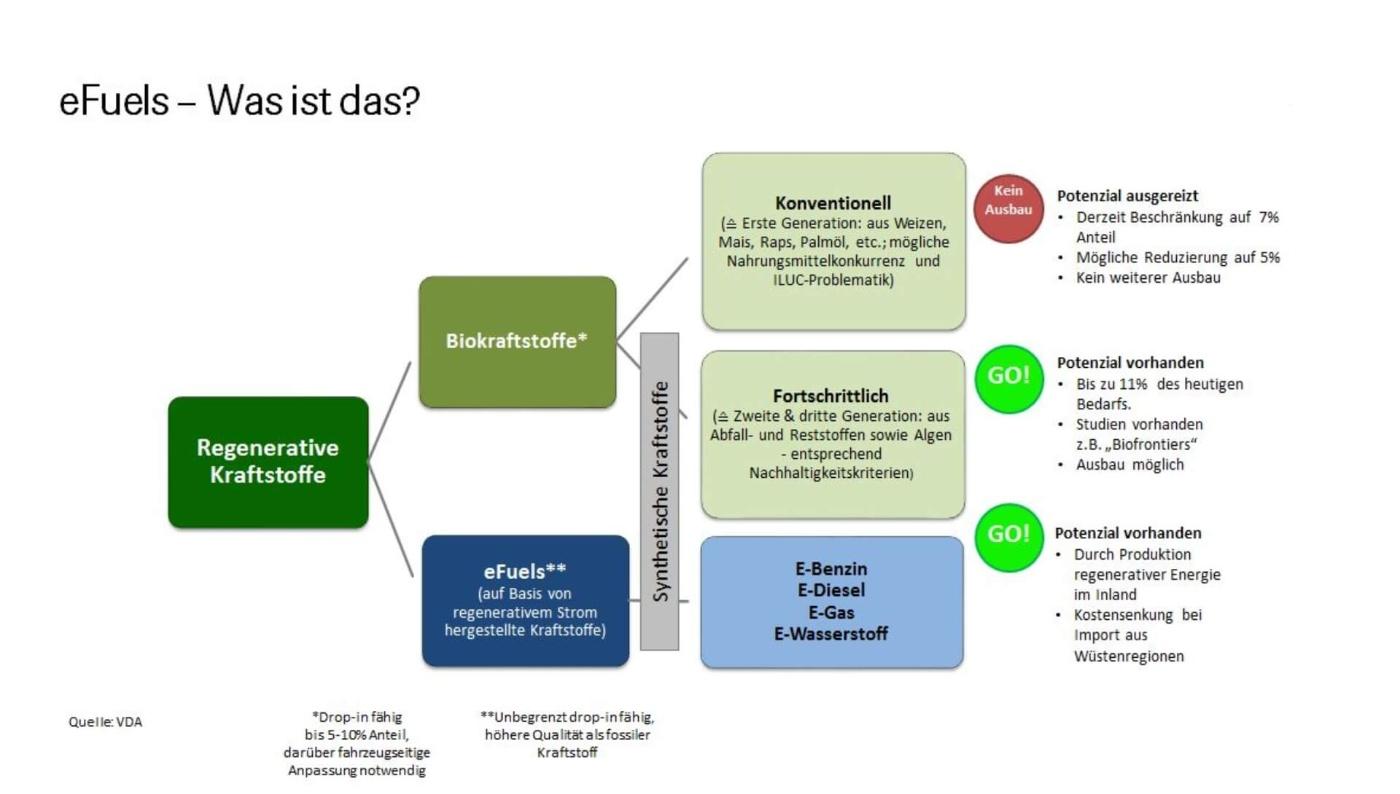

The term refers to liquid or gas fuels that can be produced from renewable sources and carbon dioxide with the help of electricity – hydrogen, synthetic petrol and diesel fuels, methane or kerosene. Power-to-X (PtX), Power-to-Liquid (PtL) and Power-to-Gas (PtG) are the terms used for the manufacture of these synthetic fuels. Unlike bio-fuels, they can be produced without competing with food production.

At the Karlsruhe Institute for Technology (KIT), they are currently investigating various processing options for manufacturing. A number of large containers grace the Energy Lab 2.0 at KIT. A box hangs on the outside, inconspicuous at first glance. It is filtering CO2 from the ambient air. However, that gas can also be obtained from waste combustion plants or biogas plants, or from the waste gases in steel or cement manufacture. In a first step hydrogen is produced via electrolysis of water, using green electricity. This reacts with the carbon dioxide from the air to form carbon monoxide and water, and produces the synthesis gas used to manufacture the fuel. From this, long-chain hydrocarbon molecules are produced. These, in turn, are the key components in the e-fuels – and, from a chemical perspective, they are no different from the molecules in the fossil fuels used today in combustion engines.

That makes e-fuels capable of being used as widely as the fuels we are familiar with: They can power the engines in use today, whether in a new car or in a classic car. That’s because the fuel is then manufactured from these molecules: primarily petrol, kerosene and diesel. Car drivers can fill up using the existing network of petrol stations, and there are no issues from mixing conventional and e-fuels. There are no changes in how you use your car day to day. But the effects on the environment are massive.

Currently, manufacture is still cost-intensive, and the fuel itself is expensive. One liter of diesel equivalent costs around EUR 4.50. However, in future they can contribute decisively to protecting the climate, as shown in a study by the German Energy Agency (dena) and Ludwig Bölkow System Engineering (LBST), commissioned by the VDA. The study suggests that by 2050 the EU’s energy requirements for transport could be met to 70 per cent and above by e-fuels, particularly for goods transportation by ship, air and road. The costs for the end-user could sink dramatically, the study finds. Imports from regions where solar and wind energy is extensively available could bring down the price of e-fuels to around one euro per liter of diesel equivalent.

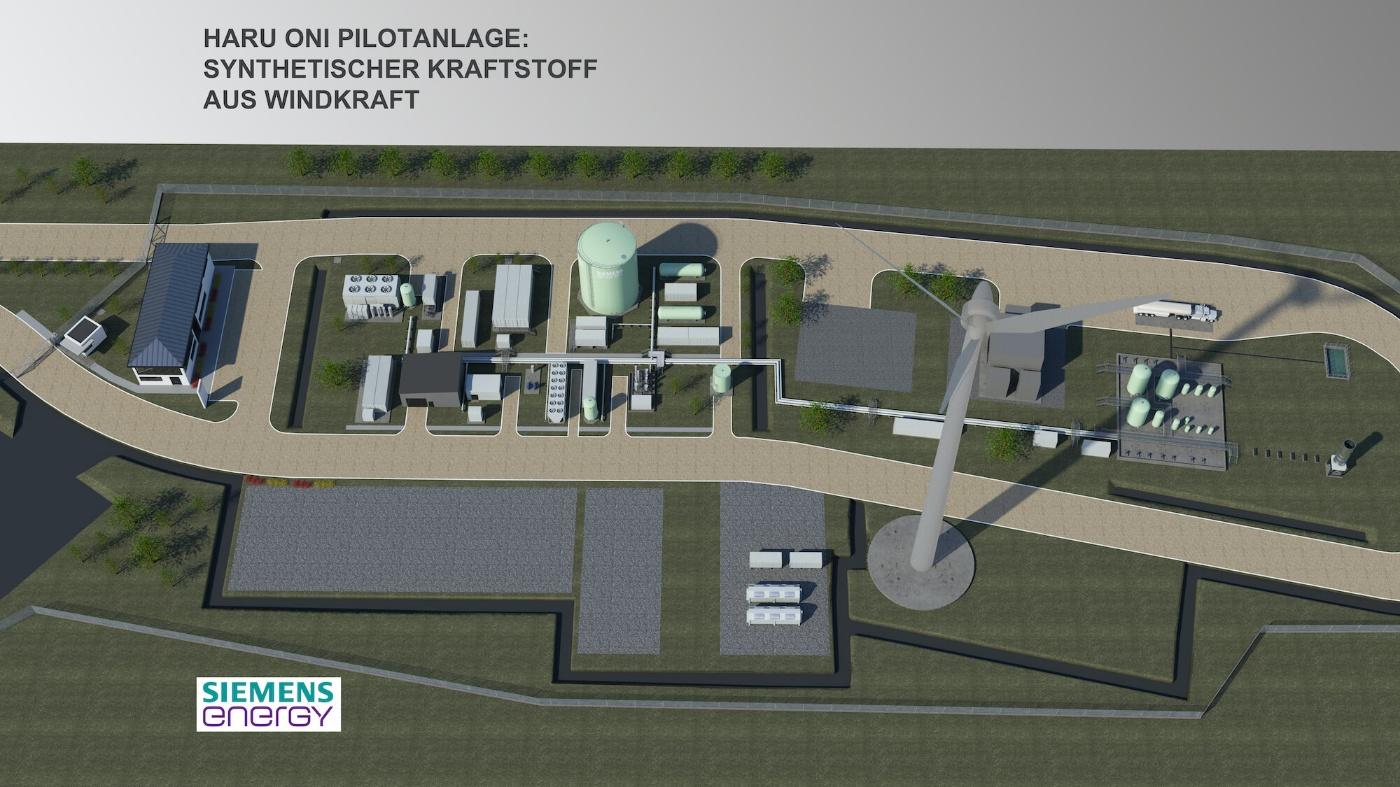

Porsche is now looking to explore this route. In Chile, the premium manufacturer is working with industry and energy partners to realize the “Haru Oni” pilot project for a commercial, large-scale plant for manufacturing e-fuel: Magallanes Province offers excellent conditions for wind-generated electricity – which will then become a main ingredient in producing the climate-neutral fuel. As early as this year, around 130,000 liters of e-fuels are set to be manufactured. By 2026, production capacity will ramp up to a forecast 550 million liters of e-fuels per year. E-fuels are a “fundamental component” if the existing car fleet is to be powered sustainably in future, Porsche is convinced.

Fuels from ecological raw materials can make the mobility of tomorrow sustainable and reduce CO2 emissions several times over – thereby making wishes come true not just for car-drivers, but for shipping operators and air passengers too: environmentally-friendly travel, with a clean conscience.